Know your Products and your Customers

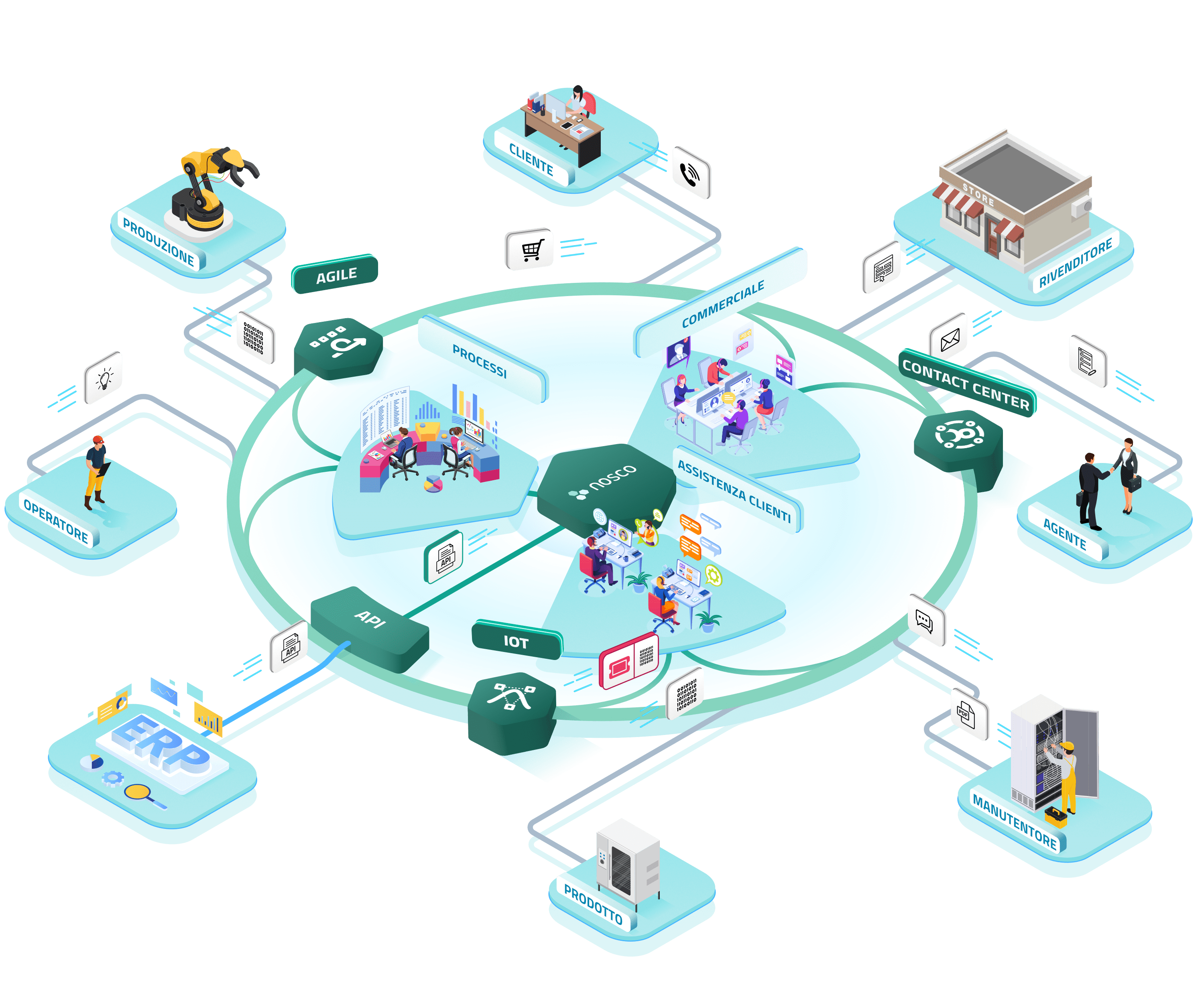

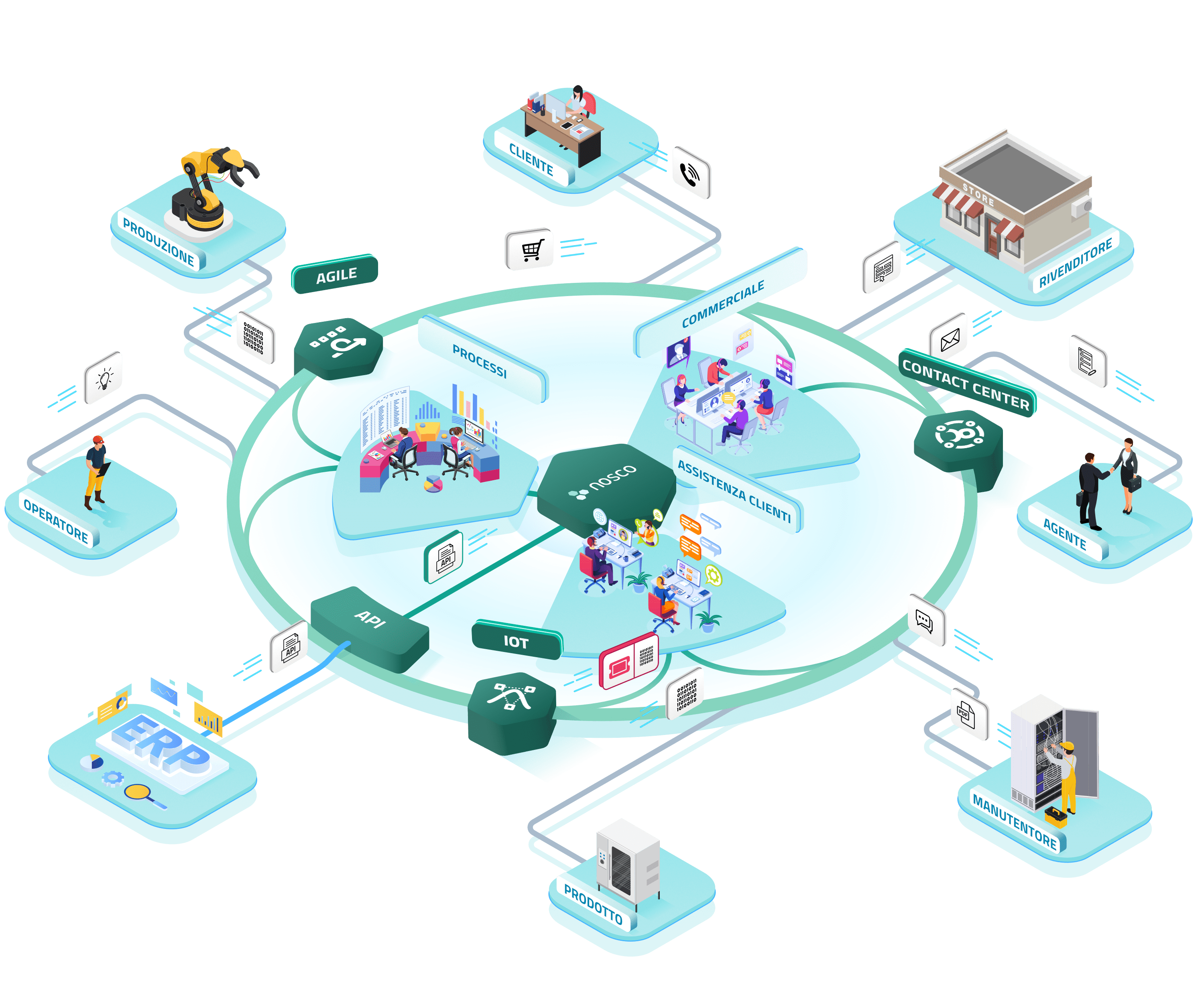

Nosco is a scalable platform that collects, organizes, manages and makes available the information that comes from your customers and connected products.

Listen

interact

learn

solve

Until recently, when a customer called to complain about a defect, there was a lot of time wasted. The call came to a switchboard or to the first free operator who listened to the problem for the first time and tried to route it to the most suitable operator. The client was forced to repeat his story several times, often losing patience.

Now, thanks to Nosco , I already know that a phone call will not come to me by chance, on the contrary, the system will have already recognized the customer's telephone number, he will have related it to other information and will have chosen me as the most suitable operator.

The last phone call received, for example, was assigned to me because I speak German, the same language as the client, and because I have skills in the type of problem that the customer indicated while on hold. I immediately planned the intervention at the customer's site by viewing on Nosco the availability of technicians.

Once the intervention is completed, the problems highlighted will become part of a shared history, allowing us to anticipate other problems also for all other customers who have the same product.

The company I work for has sold thousands of professional kitchens all over the world. We are present in Europe, China, United States, South America. Ours are excellent kitchens, resistant and reliable, but like any product, they can periodically run into small and large failures. Before choosing Nosco problem management was complex and expensive. Previously, each intervention actually began when the maintenance technician arrived on site. The maintenance technician had to be found, informed, sent and the kitchen was repaired in several interventions.

Now, thanks to Nosco , we are able to remotely dispose of product data and with a network notifications and alarms, we can even start maintenance before the customer complains. Whatever type of maintenance is needed, we have set it up Nosco in order to activate immediately the closest service and with the language and technical skills to deal with the problem. Once arrived, the service can replace the product electronics and with the App NoscoService download the original settings from the cloud and restore the operating conditions prior to the fault. The intervention becomes part of of an increasing predictive case series the perfectibility of the product itself and the frequency of faults decreases.

I have just finished testing our two-circuit chiller, the outcome is positive and the data visible on the app Nosco Factory they tell us that everything works as expected.

The quality reports have been automated and it will no longer be necessary to spend hours to fill in full sheets listlessly check list. The product has been pre-configured to connect to the cloud, NoscoIO in fact it is cloud native and the only thing it needs is connectivity. We will have a database of this testing, from which to draw valuable information also in the future.

Furthermore, all testing information is saved on the platform Nosco available to customer service , which will be autonomous in managing the breakdown. This means for them to reduce the time resolution of practices and anticipate possible future disservices.

In the very near future, most objects will be connected to the internet 24 hours a day. The products will be able to understand their operating status by analyzing their installation environment and at the same time retrieving from other products optimization's data. In essence, objects will be able to exchange data with each other, just as people do now.

My company is the market leader also because it moved in time. I have the task of developing a new business model based on digital first and I have chosen Nosco as a technology partner. The electronics of NoscoIO it is integrated into the product and thanks to its modularity we can increase or reduce its functionality. We use Nosco and the information collected during the interaction with the customer to refine our analyzes on the product, as well as to constantly improve the development of new objects and the revision of existing ones. We do this by using OpenSource resources with which Nosco it interfaces easily.